Equipment List

Our facility is prepared to meet your machining, fabrication and assembly needs.

CNC EQUIPMENT

- 2012 HURCO DCX32 CNC DOUBLE COLUMN BRIDGE MILL VERTICAL MACHINING CENTER, 126”x82.7”x36.2” TRAVELS

- 2012 HURCO VMX84 CNC VERTICAL MACHINING CENTER, 84”x34”x30” TRAVELS

- 2007 HURCO VMX64 CNC VERTICAL MACHINING CENTER, 64”x34”x30” TRAVELS

- 2008 HURCO VMX42 CNC VERTICAL MACHINING CENTER, 42”x24”x24” TRAVELS

- 2010 HURCO VMX42 CNC VERTICAL MACHINING CENTER, 42″x24″x24″ TRAVELS

- 2008 HURCO VMX30 CNC VERTICAL MACHINING CENTER, 30”x20”x24” TRAVELS

- 2012 HURCO HMX400 CNC 4-AXIS HORIZONTAL MACHINING CENTER, 15.7″x5.7″ TWIN PALLET WITH TWO 4 x 6″ KURT VISE TOMBSTONE FIXTURES

- 2014 HURCO TM18L CNC LATHE 18” CHUCK 24” SWING OVER COMPOUND 35” SWING IN GAP 84″ BETWEEN CENTERS 73HP SPINDLE WITH 6.5″ THRU HOLE STEADY REST AND HIGH PRESSURE COOLANT

- 2012 HURCO TM18L CNC LATHE 18” CHUCK 24” SWING OVER COMPOUND 35” SWING IN GAP 84″ BETWEEN CENTERS 73HP SPINDLE WITH 6.5″ THRU HOLE STEADY REST

- 2007 HURCO TMM10 CNC LATHE WITH LIVE TOOLING

- 2013 HURCO TMX10 CNC LATHE

- 2013 HURCO TMX8 CNC LATHE

- 2012 HURCO TM8 CNC LATHE 8” CHUCK 14” SWING 21.1” CENTERS WITH 2.5” BAR CAPACITY AND HB 65-1.2 MAGAZINE BAR FEEDER

- 1995 CINCINNATI MILACRON ARROW 500 CNC MILL MODEL ERE

- 1998 CINCINNATI MILACRON SABRE 500 CNC MILL MODEL EROB WITH HORIZONTAL HIGH SPEED STATION TOOL CHANGER AND 4th AXIS

- 1995 CINCINNATI MILACRON ARROW 750 MODEL ERO

- 1996 CINCINNATI MILACRON ARROW 750 MODEL ERO

- TROYKE 9” DL-9-B FULL 4th AXIS CNC ROTARY TABLE, CNC INDEXER

- Back to Top

TURNING EQUIPMENT

- TORNI TACCHI 54 ENGINE LATHE 50” SWING 276”/23’ CENTERS

- AXELSON ENGINE LATHE 24” SWING 144” CENTERS

- MONARCH ENGINE LATHE 23” SWING 84” CENTERS

- CLAUSING ENGINE LATHE 15” CHUCK 24” SWING 48” CENTERS

- WARNER & SWASEY 2-A TURRET LATHE 15” CHUCK 20” SWING 36.25” TURNED LENGTH 51.5” MAX LENGTH WITH 4.5” BAR CAPACITY

- CLEVELAND ENGINE LATHE 20” SWING 80” CENTERS

- WARNER & SWASEY #4 M-2240 ENGINE LATHE

- 1992 KENT USA MANUAL GAP BED LATHE 8” CHUCK 30” CENTERS WITH 2.0” THRU SPINDLE WITH MITUTOYO DRO

- Back to Top

VERTICAL LATHES

- 36” WEBSTER & BENNET WITH 2 AXIS DRO

- 60” WEBSTER & BENNET SWINGS 74” WITH DRO

- 60” WEBSTER & BENNET SWINGS 74” WITH DRO

- 60” WEBSTER & BENNET SWINGS 74” WITH DRO

- Back to Top

HORIZONTAL BORING MILLS – TABLE TYPE

- 4” GIDDINGS & LEWIS MODEL 340T TABLE TYPE, 48”x72” TABLE, 2 AXIS DRO

- 5″ GIDDINGS & LEWIS TABLE TYPE

- 6” GIDDINGS & LEWIS NO 56. TABLE TYPE, 72”x150” TABLE, 2 AXIS DRO, RIGHT ANGLE HEAD

- 6” GIDDINGS & LEWIS MODEL 65-86-T TABLE TYPE, 72”x150” TABLE, 2 AXIS DRO

- 4” DEVLIEG SPIRAMATIC JIGMIL 4K-96 TABLE TYPE

- Back to Top

HORIZONTAL BORING MILLS – FLOOR TYPE

- 6” GIDDINGS & LEWIS MODEL 70-H6-UF FLOOR TYPE, 360” X-HORIZONTAL TRAVEL x 120” Y-VERTICAL TRAVEL x 48” Z-SPRINDLE TRAVEL

- Back to Top

MILLING & DRILLING

- BRIDGEPORT MANUAL VERTICAL MILL 48” TABLE WITH RIGHT ANGLE HEAD

- BRIDGEPORT MANUAL VERTICAL MILL

- 2007 BIRMINGHAM MANUAL VERTICAL MILL 54” TABLE, 2 AXIS DRO

- HOUGEN MAGNETIC DRILL CAPACITY TO 2 3/4” DIAMETER 2” DEEP

- Back to Top

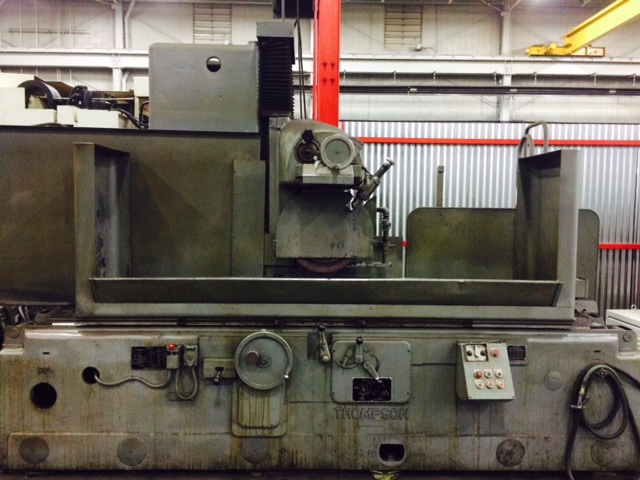

GRINDING

- THOMPSON SURFACE GRINDER MODEL C 18” x 60” W/ MAGNETIC TABLE

- LANDIS OD GRINDER 10” SWING 54” CENTERS

- NORTON OD GRINDER 6” SWING 18” CENTERS

- SUNNEN MODEL MBB-1600 PRECISION ID HONE

- ARTER 8” ROTARY SURFACE GRINDER W/ MAGNETIC CHUCK

- Back to Top

GEAR EQUIPMENT

- BARBER COLEMAN 16-16 HOBBER #12 TYPE “A”

- BARBER COLEMAN 16-16 HOBBER #12 TYPE “A” WITH DOWN FEED

- BARBER COLEMAN 14-15 HOBBER

- GOULD & EBERHARDT 24 H HOBBER 28” SWING

- GOULD & EBERHARDT 48H HOBBER 54” SWING

- FELLOWS 18” GEAR SHAPER MODEL 6A TYPE

- FELLOWS 18” GEAR SHAPER MODEL 6A TYPE WITH RACK ATTACHMENT

- FELLOWS 100” SHAPER

- PRATT & WHITNEY THREAD MILLS 6” x 60”

- PRATT & WHITNEY THREAD MILLER MODEL C-6 INCH

- ARTER SHAPER CUTTER SHARPENER

- LAPOINTE 5 TON HORIZONTAL BROACH

- BAKER KEYSEATER TO 70” OD

- DAVIS # 4 KEYSEATER

- (2x) BROWN & SHARPE CENTER DISTANCE TEST STANDS

- ROCKWELL HARDNESS TESTER

- SERVICE OFFERING BROCHURE (PDF)

- Back to Top

SAWS

- PHEONIX ARMSTRONG MODEL PA10CNC HORIZONTAL BAND SAW WITH AUTO BAR FEEDER UP TO 10” BAR

- WILTON D9040-1 VERTICAL SELF FEED BAND SAW

- MICRO T-3 3.0” ABRASIVE CUT OFF SAW MODEL C

- Back to Top

HEAVY FABRICATION

- (2x) MILLER 652 MIG WELDERS

- MILLER MILLERMATIC 251 WELDER

- MILLER MILLERMATIC 252 WELDER

- MILLER SYNCROWAVE 500S GAS TUNGSTEN-ARC OR SHEILDED METAL ARC WELDER (TIG)

- MIG, TIG, STICK, FULXCORE WELDING

- PLASMA CUTTING

- AIR-CARBON ARC CUTTING

- HARDFACING, INCLUDING COLMONOY, STOODY & STELLITE

- STAINLESS OVERLAY WELDING INCLUDING 410SS & 309SS

- IRCO AUTOMATIC TILT/ROTATE WELDING POSITIONER

- Back to Top

INSPECTION EQUIPMENT

- FULL INSPECTION CAPABILITIES AND EQUIPMENT

- 1997 BROWN & SHARPE CMM MODEL MICROXCEL 7-6-5 WITH CURRENT CALIBRATION

- SURFACE FINISH PROFILOMETER

- HARDNESS TESTERS

- DYE PENETRANT TESTING EQUIPMENT

- Back to Top

AUXILIARY EQUIPMENT

- 14’x14’x14’ VENTILATED PAINT SPRAY BOOTH

- BALDOR BELT SANDER/POLSIHER 20”

- BURR-KING 20” DISC GRINDER MODEL 20

- (2x) PEDESTAL COMBINATION BUFFER & GRINDER

- 1993 BURR ELIMINATOR VIBRATORY DEBUR MACHINE MODEL 4616

- SAFETY CLEAN MODEL 81 AGITATING PARTS WASHER

- ECONOLINE 5-120 PSI MEDIA BLASTER

- CURTIS 20HP R/S SERIES AIR COMPRESSOR

- SULLAIR 10-25 AIR COMMPRESSOR

- GRAINGER HYDRAULIC H-FRAME SHOP PRESS WITH 25 TON ACTUATOR AND 6.5” STROKE

- Back to Top

ASSEMBLY CAPABILITIES

- 9 OVERHEAD CRANES, (3x) 2O TON, (4x) 10 TON, (2x) 5 TON

- 19’ 6” UNDER HOOK

- RIGGING CAPACITY TO 40 TONS WITH IN-HOUSE CRANES (HAVE ACCOMADATED LARGER CAPACITY)

- CATERPILLAR TOW MOTOR 5,000 LB CAPACITY

- SCISSOR-STYLE MAN LIFT

- HYTORC-HYDRAULIC TORQUE WRENCH

- PARKER HYDRAULIC HOSE CRIMPER

- PORTAPOWER CYLINDER AND PUMP

- RIGID PIPE THREADER

- SHRINK & PRESS FIT CAPABILITIES

- FULL TEAR-DOWN, INSPECTION & REBUILD SERVICES

- Back to Top